SERVICES

Micro Concreting

Micro Concrete for Structural Repair and Strengthening

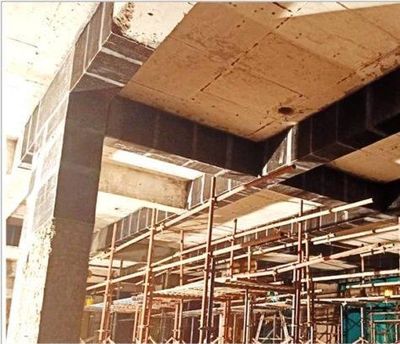

Micro concrete is a high-performance, ready-to-use material ideal for repair and rehabilitation of damaged reinforced concrete elements such as beams, columns, and slabs, particularly in confined spaces where compaction is not possible. It is extensively used for jacketing of RCC columns to enhance the load-bearing capacity of vertical members, especially for seismic retrofitting.

Key Applications

- Repair of damaged concrete structures (e.g., beams, columns, slabs)

- Grouting of large gaps

- Jacketing of RCC columns for improved strength and stability

Characteristics & Advantages

✔️ Self-flowable mixture that requires no vibration

✔️ Expansion system compensates for shrinkage in the plastic stage

✔️ High flow characteristics ensuring easy application

✔️ Rapid strength development for early reinstatement

✔️ Strong bond with old concrete ensuring durability

✔️ Moisture-resistant and chloride-free formula

Micro Concrete is a trusted solution for strengthening deteriorated structures, improving seismic capacity, and ensuring long-term structural stability.

New Industrial & Commercial Construction

We are committed to providing our customers with the best in new construction. Through careful planning and attention to detail, to the latest and best building methods, we aim to keep expenditures at a minimum while providing the workmanship usually found in higher end construction companies.

OUR SERVICES :

- FOUNDATIONS WORK S

- BRICK MASNORY WORKS

- STONE MASNORY WORK S

- BLOCK MASNORY WORK S

- CONCRETING WORKS

- PLASTER WORKS

- PAVER BLOCKS WORKS

- INDUSTRIAL TREMIX ROAD

- INDUSTRIAL TREMIX FLOOR

- ALL TYPES OF FLOORING WORK S ( TILES WORK , GRANITE WORK , MARBLE )

- COLOUR WORK

- FENCING WORK ( ALL TYPES OF FENCING WORKS )

- COMPUND WALL WORKS

- PILEING WORKS

corrosion-damage

Corrosion damage is a common kind of damage seen in constructions that are in constant touch with water or work in humid environments. But water and humidity’s debilitating effects can cause a plethora of problems.Honeycombing,excessive water to cement ratio,rusted reinforcements even before placing concrete,insufficient cover for steel from exposed concrete surface among others.Other factors such as poor workmanship and congested reinforcement in small concrete sections only exacerbate the problem.

Industrial & Commercial Renovation

We are committed to providing our customers with the best in renovation construction. Through careful planning and attention to detail, to the latest and best building methods, we aim to keep expenditures at a minimum while providing the workmanship usually found in higher end construction companies.

OUR SERVICES :

- DISMANTELING OF CHIMNEY ( INDUSTRIAL CHIMNEY )

- DISMANTELING OF OLD INDUSTRIAL STRUCTURES

- RENOVATION OF INDUSTRIAL STRUCTURES

- BRICK MASNORY WORKS

- STONE MASNORY WORK S

- BLOCK MASNORY WORK S

- CONCRETING WORKS

- PLASTER WORKS

- PAVER BLOCKS WORKS

- INDUSTRIAL TREMIX ROAD

- INDUSTRIAL TREMIX FLOOR

- ALL TYPES OF FLOORING WORK S ( TILES WORK , GRANITE WORK , MARBLE )

- COLOUR WORK

- FENCING WORK ( ALL TYPES OF FENCING WORKS )

- COMPUND WALL WORKS

Protective Coating & Waterproofing Services

While ‘as strong as concrete’ is a common saying,it is paradoxical that concrete’s diverse nature actually makes it prone to a diverse range of threats.Aggressive substances such as sulphates,chlorides,and a host of acids and alkalis are known to attack and adversely affect concrete.One of the simplest but best ways to protect concrete from this host of threats is to provide a protective coating and waterproofing,as long as they maintain basic properties of resistance to carbonation,chlorides,sulphate penetration,ingress of moisture and sufficient elongation.

Explosion & Fire Damage

Fire cause concrete surface cracking and crazing, chemical decomposition, and microcracking and spalling. These impacts can significantly change the properties of structural concrete, reducing strength and durability, and altering structural behavior.

It is a common misconception that structures which suffer fire damage or explosions cannot be saved.While it is true that the damage can be severe, especially with the sudden expansion or collapse of structural members,fire-damaged structures in almost 90% cases can be successfully repaired and restored. This is often a more cost-effective solution than demolishing the structure and reconstructing it all over again.

Fabrication & Pipelines work

In our company, we undertake different kind of fabrication project and provide extremely viable solutions. The customize fabrication project executed by our company is provided as per the client requirement and specification.

We are one of the most reliable companies dealing in unbeatable metal fabrication project services in India. We are always result oriented and timely solution provider for our valuable clients. Our certified welding professionals have good welding experience. We fabricate tanks and other projects of metal for a large range of applications. In our company, the fabrication work is certain with welding produced by our detailed process and veteran welders.

PIPELINES

We offer total range of piping system for industries including MS piping, GI piping, stainless steel piping, PP-R piping, steam piping etc.

Carbon fiber wrapping

Carbon Wrapping for columns or Carbon Fiber is widely applied in various construction categories for building maintenance or concrete structure strengthening which includes; Residential structures, Industrial structures, Commercial properties, for Industrial Chimneys and Bridges.

Carbon wrapping for columns this strengthening technique causes minimum disturbance to the structural members as compared to conventional methods. Effective use of carbon fiber reinforced Concrete or polymer could significantly increase the life of structures, minimizing the maintenance requirements. Carbon wrapping for columns are resistant to corrosion; hence they are used for corrosion control and rehabilitation of reinforced concrete structures. Carbon fiber reinforced Concrete and Carbon wrapping for columns is also widely used to strengthen concrete structures.

Advantages :-

Strengthening of reinforced concrete, masonry, brickwork and timber elements or

structures, to increase flexural and shear loading capacity for :

Improved seismic performance of masonry walls

Replacing missing steel reinforcement

Increasing the strength and ductility of columns

Increasing the loading capacity of structural elements

Enabling Changes in use/alterations and refurbishment

Correcting structural design and / or construction defects

Increasing resistance to seismic movement

Improving service life and durability

Structural upgrading to comply with current stand